| |

Ned Kelly Steve Hart Joe Byrne Dan

Kelly

Ironicon Kelly gang

helmet replicas,

1/

3rd scale

A

most iconic

image of Australian folklore must be that of Ned Kelly's slotted helmet.

The gap through which he viewed that 1880 Glenrowan misty morning can

be imagined as the first wide - screen experience, horrible for its

dramatic outcome. The image lingers in our mind as a symbol of his daring

, and which has made him an Australian Iron

icon.

Revered by some but not all, none can argue that ‘Ned’ created

immortality for himself with that romantic notion for self preservation

behind a suit of armour. The suits and helmets were made from stolen

plough mould boards that were heated and wrought on a crude bush forge.

This unique idea was best put by Keith McMenomy “ the finished

result was as unique and impractical as it was true to Kelly’s spirit; a

grand misguided gesture.”

By whom and where the armour was made remains a guarded family secret, but

it was claimed that Tom Lloyd and Dan Kelly made the helmets and suits on

Kelly's own bush forge at the Eleven Mile Creek family farm. Tom Lloyd

was cousin to Ned and the fifth member of the gang although he was never

implicated. The reason these details were not released was probably to

cover up and protect Kelly sympathisers who had helped the gang survive

during those extraordinary times,

( local Blacksmiths included ) .

It has recently been proven that Joe Byrne's helmet had been made in a

bush forge.

ANSTO, Australian Nuclear Science and Technology Organisation) tested the steel by X-ray fluorescence: The results

showed the steel never got above 700 to 750 degrees C (cherry red) and

consistent with a very hot bush fire.

See, Not Just

Ned

http://www.nma.gov.au/exhibitions/irish_in_australia/bushrangers

Background images are of 1/3rd

scale ironicon replica helmets

Regarding these ironicon

Kelly gang helmets. I set out to create these models using similar

techniques to that of the bush blacksmith. The miniature originals were

made of hard wax giving a malleability similar to that of red- hot metal.

Each plate was carefully measured, mapped, beaten and wrought into a

likeness of the original parts. All dents, scratches, dings etc were

included. The wax models were lost during the tool making process. No

expense was spared in their making.

These helmet miniatures are exact die cast copies* of those lost wax

models. Although they are very accurate as 1/3rd scale models, there

are exceptions as some of the nuts and bolts were square, and on

Dan’s helmet, the visor was riveted. There are also some holes around the

back of the helmets that I excluded as I could not be sure of their

location or function without a lot of further research.

Each piece has been hand crafted to a high level and mounted on wood from

Kelly country - specially selected for the purpose. As we could never own

the originals, these models are the next best thing. The helmets can be

removed from the stand if so desired. Very Australian made. *Copyright is

claimed, Bill Denheld.

Pictured below: Ned's 1/3rd scale helmet here shown approximately actual

size.

Key to numbers;

1 four pairs of holes were punched through the 1/4 inch steel plate

around the top edge probably to hold the work in place during

blacksmithing.

The holes also served to attach a soft lining. Each of the four helmets have this feature indicating a

similar helmet forming procedure and the maker.

2, Often mistaken for a bullet strike dent, this is more likely a

heavy punch mark as it is flat bottomed. The description for this dent at

State Library of Victoria where the original is on display says it is

caused by a Martini Henry rifle bullet strike, however I believe it is

caused by a punch as there appear two strikes one atop the other, and also

the other bullet strikes were also caused by similar caliber bullets, so

why doesn't this strike look similar to the other two.

3 & 4, Bullet strike

direct hits. Most likely from .45 cal Martini-Henry or .50 cal Spencer rifles.

5 & 6,

Countersunk bolt holes for holding the former plough shares to the frame

of the plough, about 3/4 inch diameter.

On Neds helmet

the visor part has been blacksmith welded. A & B, This would have

been a tricky bit of work on a wood fired forge. There is an issue here as

to whether it is possible to do that on a bush forge because the metal

would need to be at least white hot. It was proven that Joe Byrne's

helmet and suit was made at relatively low temperatures 750c, Ned's helmet indicates much

higher temperatures. On Neds helmet

the visor part has been blacksmith welded. A & B, This would have

been a tricky bit of work on a wood fired forge. There is an issue here as

to whether it is possible to do that on a bush forge because the metal

would need to be at least white hot. It was proven that Joe Byrne's

helmet and suit was made at relatively low temperatures 750c, Ned's helmet indicates much

higher temperatures.

B, at the visor corner there is a small tear in the metal

indicating vigorous manipulations to get it to go around the front. Note

the hammer marks along the joint. Can we invite a blacksmith today to

provide samples of forge welded steel plate? Now

here's a challenge.

Picture shown is of the 1/3rd scale Ironicon model.

Of the four helmets, Joe Byrne's is the better design,

each has its own strong points. It would appear that each individual

member of the gang had a deciding factor as to how he wanted it done,

after all he had to wear it.

|

Joe Byrne decided to reduce the eye slot to an absolute minimum. A

bridge across the nose give the out look a goggle effect. To make such

a careful deliberate profile would require a lot of filing. There are

no burrs or sharp edges even though the metal is getting very thin

around the shoulder contact areas.

On the real armour the flared shoulder metal is paper thin.

( below

right )

|

|

Model is on

the left,

the real Joe Byrne armour on the right can be compared. Camera angles are never quite the

same, however see the subtle similarities of both.

I would estimate the helmet metal is much thinner than the others,

which may explain the better workmanship exhibited on Joe's entire

suit. |

|

The designs are quite different yet techniques indicate the same maker.

Dan's helmet (left) has a separate visor, the others have an L shaped

blank wrapped around and bolted with one bolt. Joe's helmet ( middle ) has

thinner steel indicated by deeper hammer dents from inside. Steve's

(right) has a vision slot overly large, but probably much easier to

look through and not so critical. We can not be sure which was Steve's or

Dan's as both their bodies were burnt beyond recognition in the fire of

the Glenrowan Inn. Joe was taken from the Inn before the fire took hold.

It is ironic that Joe was killed by a bullet to the groin which passed

between his breast plate and his lap apron, yet he feared a fatal bullet

passing through the gaps more than the others, his eye slots were

testimony to that.

Since making the replica

armour helmets, I have formed the theory that the four helmets were made

by the same people. J.J. Kenneally's book of 1929 says they were made by

Dan Kelly and Tom Lloyd. That's fine,- with Dan dead, and Tom taking the

blame for the suits, this leaves others who helped make these

liability suits 'off the hook' so to speak.

Ned's helmet certainly

indicate high level of skill as the visor area was welded to the

cylindrical helmet shape. None of the others have this feature. This

welding was done by heating to above white hot and bashing and blending

the metal together forming a welded joint. This is not an easy task.

This welding suggests

a difficult and skilled maneuver, a capable skill of a trained

blacksmith. The other three helmets have not used this procedure and

they adopted an L shaped blank to be cut out from the plough share. This

was much easier as no welding was required but required large sized

plough shares.

I believe Ned's was the first to be made for this reason, -you would not

want to do it the hard way if the easy way was proven to be OK. There was

also a question of economy, - the amount of surface area of steel

required. From a design point of view Ned's has low fixing bolts which

could be seen as a flaw in the design as the mask could flip forward

onto the chest if the bolts were not tight enough. All other three

helmets have high bolt fixings - indicating better design decision

to adopt the higher bolt holes. ( After Ned's was made)

Also, Ned's Helmet is rather deep in the mask as with Joe's helmet being the

deepest. Dan and Steve's helmets have rather short masks by comparison.

Dan's helmet still has a plough fixing hole whereas Steve's does not. Dan's has a

riveted visor indicating metal was running out (without finding more

ploughshares). By attaching the visor with two fixing points, smaller

pieces of steel could be used. I believe Joe Byrne's and Dan's helmet

were the later to be made.

All background images are of 1/3rd

scale ironicon replica helmets

Joe's helmet shows more

refinements over the other three. It has more form and fit. See the

shoulder flares, fine detailed eye slots to minimize bullet exposure, a

general better level of care in the visor end shape and bolt hole.( a

more sophisticated design) It was also a slightly thinner steel than the

others which helped to mould it better to the shape required ,

and probably the last to be made.

An interesting finding by ANSTO ( Australian Nuclear Science and

Technology Organisation ),

Joe Byrne's suit was made with temperatures

no higher than 750 degree C, where as Ned's welded visor would require

considerably higher temperatures( up to 1000 C). This indicates Ned's was

probably made by a blacksmith at his forge. Once a technique was

established, the boys adapted there own ways to solve the manufacture

problems and opted a home made bush forge using charcoal. ( a lower

level of heat as indicated by ANSTO on Byrne's suit)

A common feature exhibited on all four are the sets of 2 holes around

the top circumferences.

These indicate a jigging feature required to

form the red hot metal around a form. ( a green log into which 2 large

spikes were hammered in ). These spikes served as a holding point to

stop the steel from moving around as it was struck again and again. The

other end of the red hot steel was held by blacksmith tongs. Each time

the metal needed re-heating, the spikes were pulled out and replaced

when more shaping was required. Although some historian believe the

pairs of holes were put in to offer a fixing for woolen lining like a

sewn in 'beanie', if that was so, why didn't they place the holes down

near the ears level?

Where

to purchase a truly Australian

ironicon

Benalla

Art Gallery, shop ( by the

lake). Bridge Street Benalla Vic 3672 Ph 61-3 5762 3027

Beechworth Gold, Legends of Beechworth.

Cnr. Camp and Ford St Ph 61-3 5728 3388

Featured Wood Gallery 5 Piggott Drive, Australind, West Australia

6233 PH 61-8 9797

2411

Glenrowan, Cobb& Co,

37 Gladstone Street Glenrowan Vic 3675 Ph 61-3 5766 2409

Museum Victoria, shop Carlton Gardens, Nicholson St Melbourne 3000 Ph 61-3 8341 7620

Old Melbourne Goal, shop (top

end) Russell Street Melbourne 3000.

Ph 61-3 9663 7228

Recommended Retail Price around Au $

165 each - excluding postage.

Allow $20 for regular, or $30 for Express Parcel Post to anywhere in Australia.

(Note: this postal parcel bag can contain 2 helmets for the same postal

cost)

Have trouble to purchase? contact the maker direct.

Ph 61-3 9725 8910

see

www.ironicon.com.au

where Ned gets a fair go

|

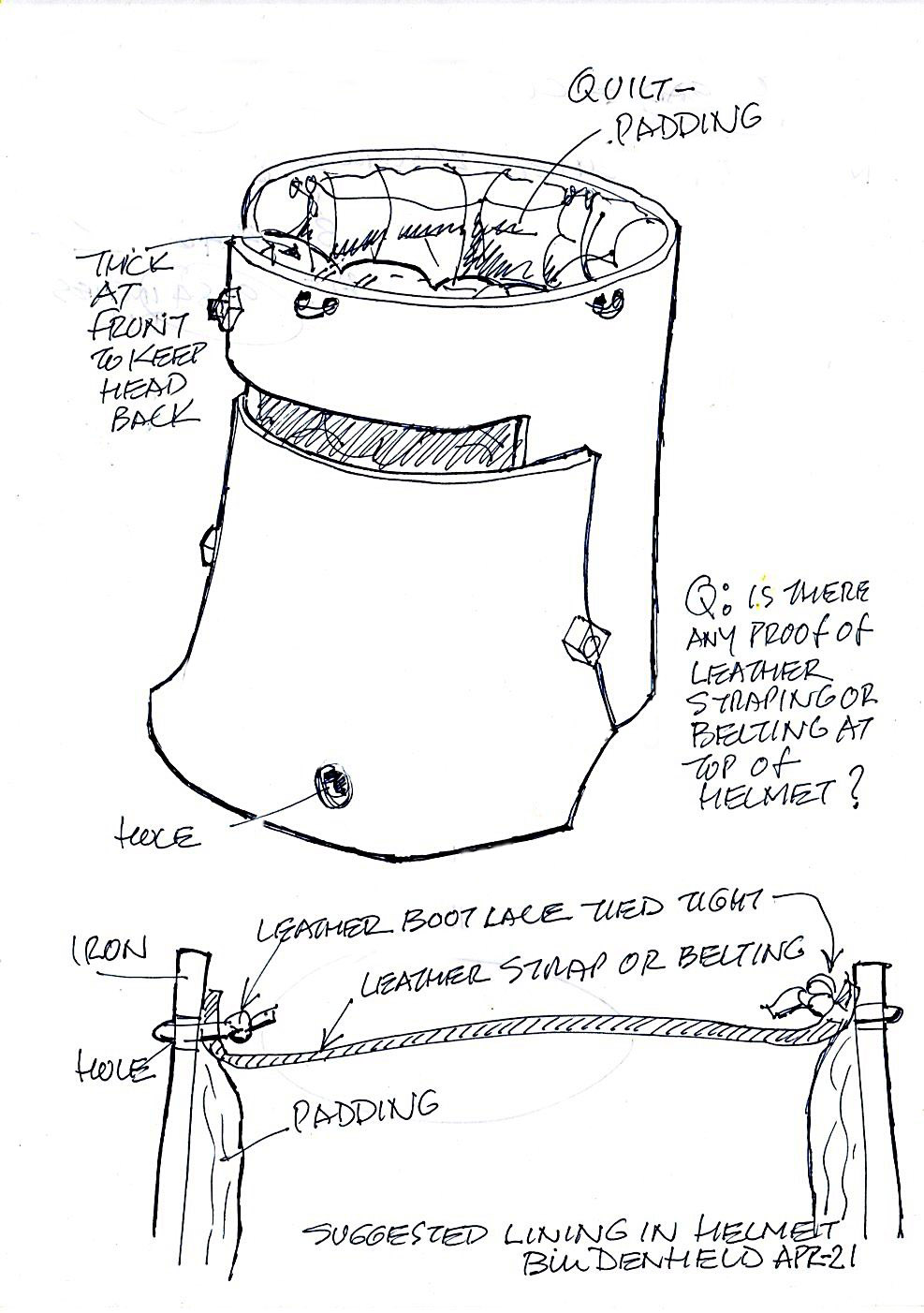

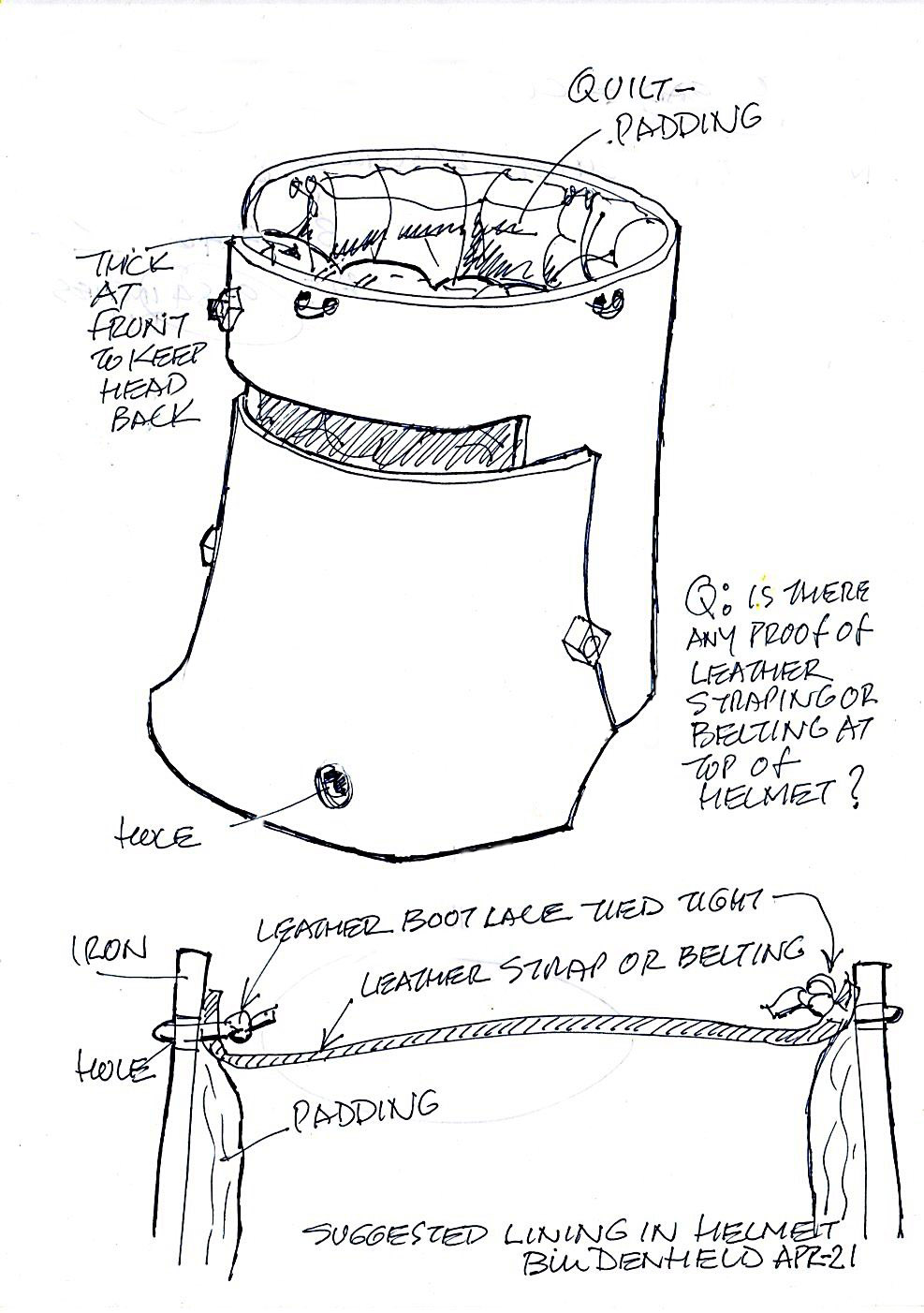

Pictured below: is the quilting of the

armour. Image drawn for the article linked.

|